Long live the locomotive- the story of the Porter-Cable Take-About-Part three

We've discussed the G-3, the Guildtool belt sander that escaped obscurity by leading to the development of the modern worm drive belt sander. Now it's time to turn our attention to the Guild sander that no one liked but people, and the descendant of the G-3 that still defines the belt sander to generations of woodworkers to this day. I refer to the 2-A/A-2 and A-3/504 sanders.

I've mentioned that the Guildtool line was directed at the home hobbyist as an affordable line of power tools at a time when there really wasn't such a thing ( other than the drills that everyone and their maiden aunt cranked out-those were legion). A belt sander is hard to cheapen up without sacrificing quality ( not that this has ever stopped anyone, Black and Decker), and while the G-3 tried to reduce costly hand finishing by being rectilinear, the 2-A approached the issue from a more cutting edge (in 1936) standpoint.

The original 1936 Guildtool 2-A, loved by everyone but the W.P.B.

This little fellow ( 2"x21" belt) is chiefly made from die castings, which had been pioneered in everything from appliances to ashtrays but was largely uncharted territory for a power tool at the time. What few tools that used this technology were lackluster at best, but the 2-A was quite a different story.

Die castings made the sander lighter (9lbs) and more compact, but the greatest advantage accrued was the dramatic reduction in labor required to turn a raw casting into a finished piece. The 2-A was still hand fit (that would be the case with most Porter-Cable tools until the development of the 346/315/368 platform of saws in the early '60s), but the castings came out of the machine with a much finer surface, which took less time to polish up.

Additionally, the 2-A ( or, as it soon became known, the A-2) forewent the separate worm of the earlier sanders , having it cut into the end of the armature shaft. This feature (I'm using the term loosely) would not be repeated in other sanders, but it saved labor, machine time, and space, all of which made the petite A-2 thirty dollars cheaper than the T-33 by 1947 ( that's about 350.00 in today's money). Being such a felicitous combination of inexpensive, well constructed and of handy size for smaller projects, the A-2 was hugely popular, so popular that Porter-Cable had to have two motor manufacturers producing fields and armatures to meet demand (should you disassemble an A-2, a brown armature and field were made by Dumore; a motor with blue laminations was from Robbins and Myers. Don't mix and match, they aren't compatible). In fact, the only hiccup in the entire twenty-two-year production run was the period in 1944 when manufacturing of the A-2 was halted by order of the W.P.B. for the duration of WW2.

By 1953, the A-2 was incorporated into the main line of products, where it would stay until 1958 when the first belt-driven sanders were introduced. Unable to compete, the A-2 was discontinued. While the belt drives were cheaper and used wider belts, they had poor balance and were less robust as our little fellow, whose only true drawback was the need for the worm drive oil to be kept topped off. The concept of a compact worm drive sander would be revisited during the 2000s in the form of the 371, but let's face it, those kinda sucked.

Meanwhile, a new sander would see light during the war that married the technological advances of the A-2 with the innate durability of the T-33, and did it so well that it would outlive all the other Take-Abouts, including the ones that came after it.

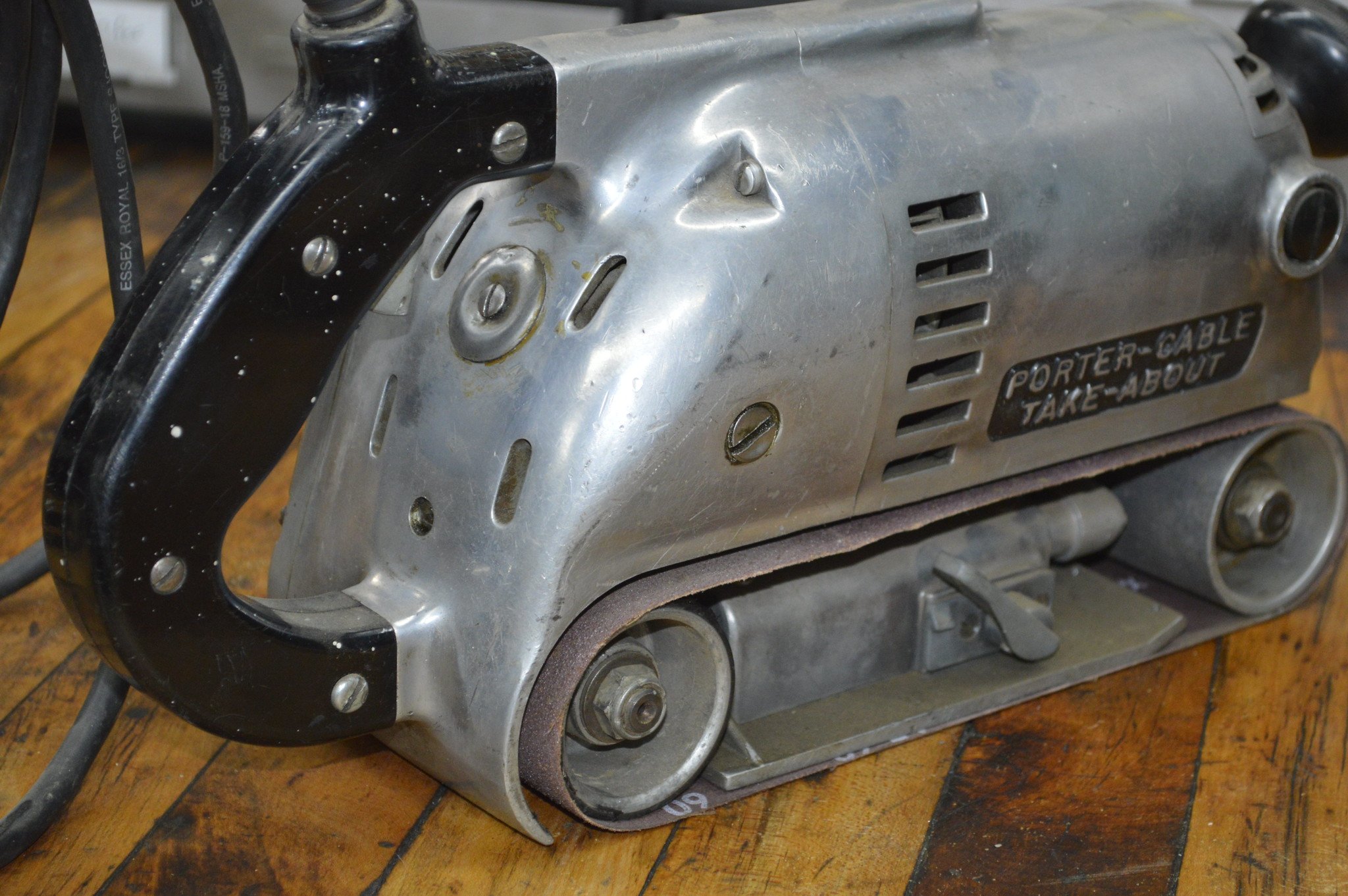

Say hello to the iconic A-3.

The A-3, c. 1948. The gold standard of belt sanders for the next 67 years or so.

Appearing in 1944, the A-3 is, in essence, a T-33 sander stripped down to its fighting weight. The A-3 was die-cast throughout, which gave it the weight and labor savings of the A-2, but it retained the T-33 performance envelope and even shared a gear set with its predecessor (at first). The A-3 wasn't a winner right out of the gate, though. The earliest version was somewhat lacking in ventilation, requiring lower air slots to be milled into the front endshield.

There is also the small matter of the expansion plug fitted into the frame to access the gearbox. This system works well enough if snugged up judiciously, but is easily deformed by being cranked down, and many early A-3 sanders bear a layer of silicone or JB weld slathered over this plug like margarine on a cornbread biscuit.

The A-3 was quite popular. There was even a version made with an air motor ( for the factory where air lines were more frequently encountered than 115 volt receptacles), the 61-E, made for them by Rockwell's Buckeye Tools division in Dayton, Ohio,

The equivalent of your vegan aunt, the 61-E eschewed the usual diet of electrons.

While several minor details changed throughout its production run, the basic blueprint was sound enough that it survived through the Rockwell years ( renumbered as the 504) and the Pentair period, only to be felled five years later like a mighty oak by the bloodstained, money-grubbing hands of those unmitigated bounders who make everything out of yellow plastic. Production would cease after sixty-seven years, making it the longest-produced handheld power tool of all time.

There are better sanders than the A-3. If I'm honest, it doesn't even make my top five. A-3's are easily damaged if they get dropped. They were built so lightly that later versions had additional wear plates scabbed on to counteract the effects of a poorly tracking belt. They're prone to loose brush holders, oil leaks, and derangement of the idler pulley support arm if dropped. Think of a T-33, take away the impressive airflow and ruggedness, and you have an A-3.

That being said, I've easily repaired a hundred of them in the last twenty years, they're fast and light, and I've seen them survive abuse that would promptly murder a modern belt-driven sander.

Then, of course, there's my personal experience with the breed.

My A-3 was bequeathed to me by an old customer who has long been in his grave. He purchased it in '48 when he got out of the Army. He used it and a K-75 circular saw to build homes for decades, and when his oldest went to work with him in the '60s, the son went and bought his own, which saw just as much use. They even went so far as to buy a third in the late '80s. I repaired a number of tools for this man over the years, and when he brought the sander in for service and we talked about what a great sander it was, how much he used it and how it put food on the table for his entire working life, he slid it across the bench to me and said that he wanted me to have it. I'm a fairly stoic fellow in general but damned if I wasn't misty-eyed. I rebuilt it, of course, and while it isn't my go-to sander, I still take it off the shelf for the odd sanding job. I'll never part with it on this side of the river, and I hope someday I can pass on Mr. Sherman's act of kindness to a fourth generation of admirers.

So yeah, I like the A-3 well enough.

The team:

2-A/A-2: 2"X21" belt, 600 fpm,,9 lbs, Dumore or Robbins and Myers motor

A-3/504:3"X24"belt,1600 fpm14 lbs,3/4hp motor

Nothing succeeds like success, and these two sanders were very, very successful. But they stood in the shadow of their contemporary (literally, it was quite a bit bigger), which I maintain is the all-around best worm drive belt sander ever made, the big, beautiful BB-10.